The Soohow Instrument Direct Reading Spectrometer is widely used in the analysis of element content in steel and non-ferrous metal materials. It can quickly, accurately, stably, and simultaneously measure dozens of analytical elements, meeting the needs of industrial research and development, process control, feed inspection, product sorting, and other aspects.

AES998 is equipped with a high-energy spark plasma power supply system and an optical system with high focal length and resolution in the industry, achieving high levels of accuracy, repeatability, and stability for high-speed metal detection.

High energy spark plasma power supply system

High energy range, high reliability plasma power supply system releases high-quality electric sparks.

It can accurately analyze various matrices and has unique advantages in analyzing difficult to excite cast iron and cast aluminum materials.

High performance optical systems

The AES998 optical system with high focal length and resolution in the industry provides a powerful spectral analysis platform, with high spectral analysis accuracy and strong reliability; The optical system is stable and has a long calibration cycle.

Optimization of excitation platform design

Adopting a dynamic and static argon gas flow design, ensuring timely analysis of samples without the need for a heat engine during analysis; And low gas flow consumption during standby, saving argon gas.

The optimized argon blowing airflow design effectively discharges metal vapor and promotes stable discharge of electric sparks.

The design of the protective door effectively isolates noise and electromagnetic interference, prevents accidental excitation of un sampled products, and provides protection for testing personnel.

Convenient user experience

From sample processing to instrument operation, the process design is simple and easy to operate, and part-time personnel can perform daily operations.

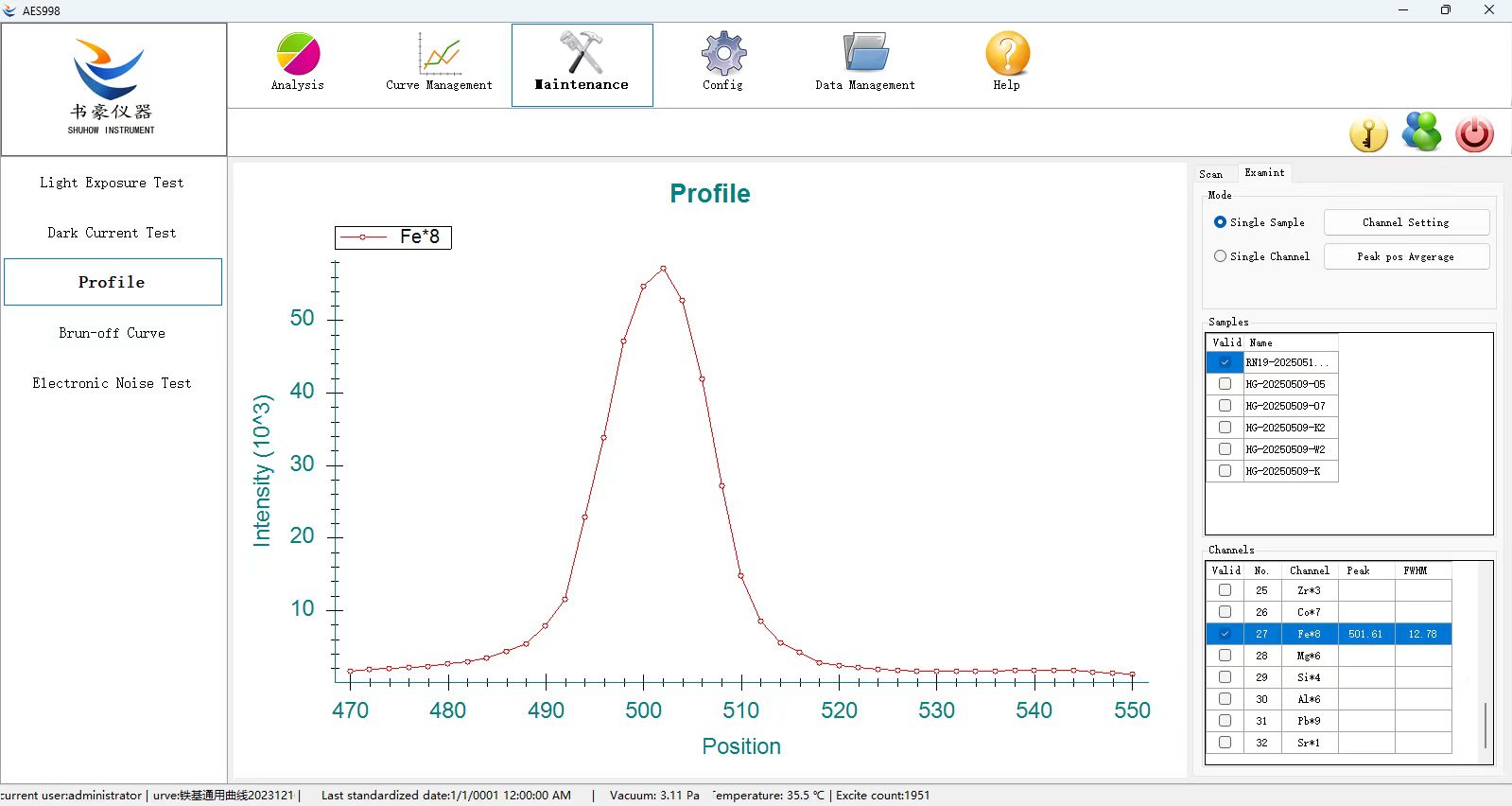

WINLAB software system visualization operation design, operation and maintenance functions are clear at a glance, and testers can quickly learn and operate.

Hardware status monitoring protection

Real time monitoring and display of instrument status, automatically protecting the instrument system when it exceeds the state range

Application field:

Aerospace field

Automotive components

metal smelting

Metal trace element detection

Optical system

Optical structure: Paschen Runge structure;

Grating focal length: 998.8mm;

Concave grating: Line density: 2400gr/mm, dispersion rate 0.47nm/mm (Level 1);

Slit width: Incident slit: 20 μ M; Exit slit: 35-100 μ M;

Light chamber filling: vacuum type (vacuum degree ≤ 3Pa) or air type, constant temperature control ( ± 0.1 ° C);

Spectral range: 130-780nm (vacuum), 130-780nm (air);

Maximum channels: 48;

Detectors: Φ 13mm Φ 28mm, 10 level side window photomultiplier tube.

Excitation station

Type: Argon gas flushing, protective door design;

Special samples: small sample fixtures can be provided.

Spark power supply

Software: Soohow WINLAB software, which can automatically calculate, calibrate, and store;

Argon gas: purity greater than 99.999%;

Dimensions: 1800 mm long * 1050 mm wide * 1245 mm high;

Weight: Approximately 500 kg;

Environmental requirements: Room temperature 15-33 ℃;

Power supply: 220V+/-10%, single-phase, 50/60 Hz, independent ground wire.

Features and advantages:

High energy spark plasma power supply system;

High energy range, high reliability plasma power supply system releases high-quality electric sparks. It can accurately analyze various matrices and has unique advantages in analyzing difficult to excite cast iron and cast aluminum materials;

High performance optical systems;

The AES998 optical system with high focal length and resolution in the industry provides a powerful spectral analysis platform, with high spectral analysis accuracy and strong reliability; The optical system is stable and has a long calibration cycle;

Optimization of excitation platform design;

Adopting a dynamic and static argon gas flow design, ensuring timely analysis of samples without the need for a heat engine during analysis; And low gas flow consumption during standby, saving argon gas;

The design of protective doors effectively isolates noise and electromagnetic interference, preventing accidental excitation of unreleased products;

Convenient user experience;

From sample processing to instrument operation, the process design is simple and easy to operate;

WINLAB software system visualization operation design, clear operation and maintenance functions at a glance, allowing testers to quickly learn and operate;

Hardware status monitoring protection;

Real time monitoring and display of instrument status, automatically protecting the instrument system when it exceeds the state range.