The PDA100 portable automatic wear particle analyzer is a portable instrumentation system based on video streaming, high acquisition rate, dynamic imaging analysis, and intelligent wear particle recognition and classification. This instrument is primarily designed for monitoring contaminants in engine lubricating oil, aircraft hydraulic oil, aviation fuel, and transformer oil. It can automatically sample oil specimens of varying viscosities and directly capture morphological images of particulate contaminants. The built-in automatic abrasive particle intelligent recognition algorithm software calculates the area and equivalent circular diameter of particle contaminants in accordance with ISO 11171, and outputs the quantity and classification of the particles. It enables counting of particles larger than 4 μm, concentration measurement for particles between 5–10 μm, and automatic classification of particles larger than 20 μm into categories such as cutting wear, sliding wear, fatigue wear, non-metallic abrasives, fibers, water droplets, and bubbles, with concurrent direct image visualization.

Technical Specifications of the Portable Automatic Abrasive Particle Analyzer | |

Product Model | PDA100 |

Detection Principle | Microfluidic Imaging Recognition Technology |

Detection Range | 4~200μm |

Optical Magnification | 5× |

Industrial Camera | 1.3-megapixel CMOS camera; resolution 1280 × 1024; |

Test Subjects | Contaminant particles in lubricating oil including copper, iron, fibers, bubbles, water droplets, sludge, and other impurities |

Contamination Index | NAS1638, ISO4406, GJB420 grades and particle counts; additionally supports user-defined contamination counting, segmentation, and grading methods |

Particle Type Output | For particles larger than 20 μm, performs intelligent classification into cutting wear, sliding wear, fatigue wear, non-metallic abrasives, fibers, bubbles, water droplets, etc., with the ability to output individual particle images for inspection |

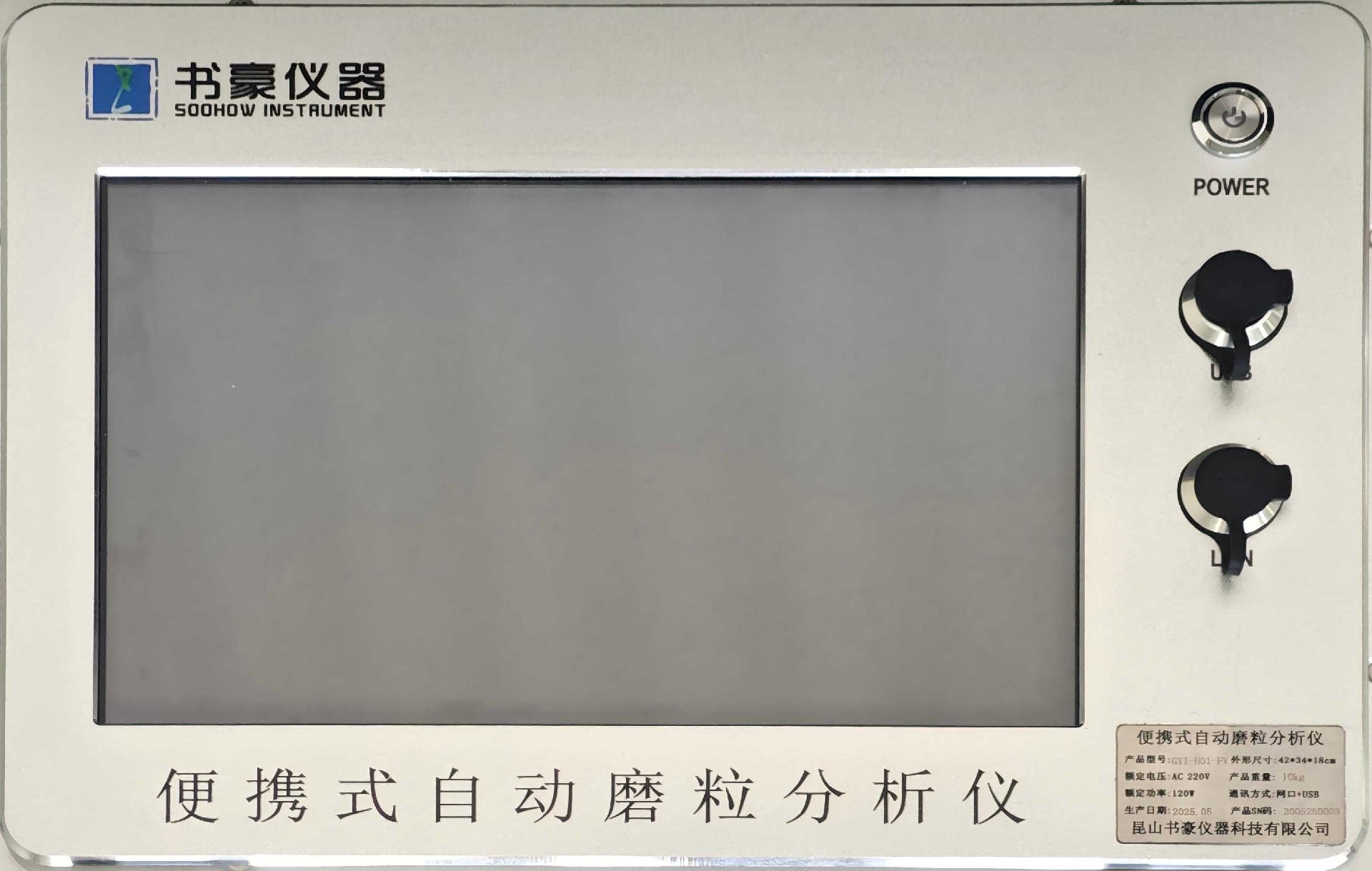

Display | 12.1-inch 1280×800 color LCD with touchscreen operation |

CPU | 8-core 64-bit processor; Four Cortex-A76 cores and four Cortex-A55 cores with a dedicated NEON coprocessor; Cortex-A76 clock speed up to 2.4 GHz, Cortex-A55 clock speed up to 1.8 GHz |

GPU | Integrated ARM Mali-G610 GPU; Built-in 3D GPU; Compatible with OpenGL ES 1.1/2.0/3.2, OpenCL 2.2, and Vulkan 1.2 |

NPU | Embedded NPU, supports INT4/INT8/INT16/FP16 precision, computing power up to 6 Tops |

RAM | 16GB |

Storage | eMMC 256GB |

Interface type | Nylon tube with 3 mm outer diameter and 2 mm inner diameter |

Detection time | Less than 1 minute |

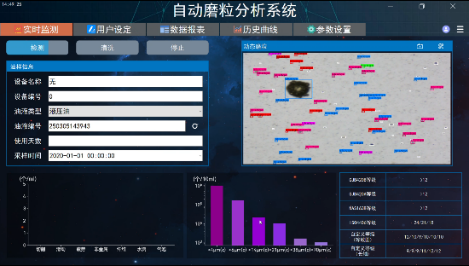

Analytical Functions | The instrumentation software provides custom editing and management functions for oil samples or devices, allows querying of historical detection data reports, performs statistical trend analysis of equipment wear, contamination levels, and particle counts, and can automatically generate analysis reports. |

Operating Temperature | -20℃~60℃ |

Operating Voltage | DC 24V or Power Adapter |

Maximum Power | Less than 100 W |

Output Port | USB/RJ45 |

Housing Material | PP, Aluminum Alloy |

Weight | 10±0.2kg |

The instrumentation utilizes an image-based contamination detection principle, capable of eliminating interference caused by bubbles.

The instrumentation employs 5x optical magnification for detection, achieving performance and magnification levels significantly surpassing comparable products in the industry.

Capable of simultaneously outputting contamination levels as well as the wear particle types and quantities of typical wear particles per unit volume;

The instrumentation's built-in detection module employs a large depth-of-field, high-resolution optical system capable of analyzing the color and contours of particles such as iron, copper, fibers, bubbles, water droplets, and oil sludge. This enables precise classification and sizing of particle attributes, along with the capability to output spectra of individual typical particles for viewing and analysis;

The instrumentation software allows users to define contamination counting, segmentation, and grading methodologies in accordance with customer enterprise or internal contamination standards;

The instrumentation software includes functions for custom editing and management of oil samples or equipment, historical data report retrieval, device wear analysis, contamination level assessment, and particle count trend statistical analysis.

The instrument incorporates automatic sample intake and cleaning functions, with monitoring of sample cell cleaning effectiveness via software; the durations for automatic sampling and cleaning are configurable.

The instrument includes a built-in high-precision metering pump with a sample intake accuracy of 0.1 μL, ensuring high-precision quantitative detection and analysis.

The instrument’s contamination level can be automatically calibrated using standard reference materials, supports third-party metrological calibration, and provides corresponding third-party test reports.

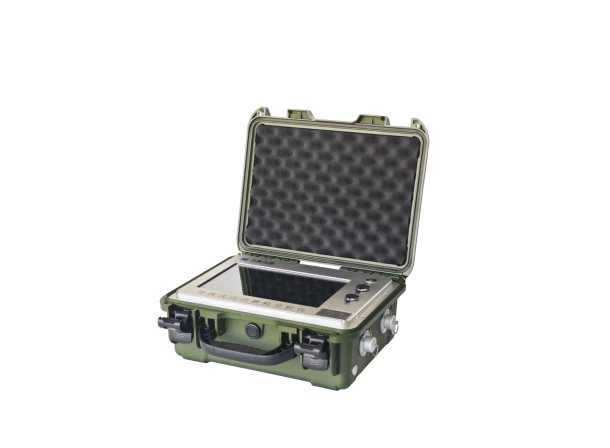

The instrument features a high-strength injection-molded housing with a compact structure and lightweight design, facilitating portability.

The instrument panel is manufactured using a high-precision integrated aluminum machining process, resulting in a simple, aesthetically refined, and durable construction.