The Oil Analysis Spectrometer is a rotating graphite disk electrode oil analysis spectrometer developed and designed based on the principle of atomic emission spectroscopy for oil analysis. It mainly consists of a high-energy arc excitation power supply system, a rotating disk and rod electrode excitation device system, a Pashen Runge full point and surface diffraction spectroscopy system, a highly CCD electronic measurement and control system, and a professionally developed computer analysis software system. Specially used for accurate quantitative determination of the composition and concentration of trace elements dissolved and suspended in various synthetic or mineral lubricating oils. Widely used in military, aviation, marine, land transportation, mines, power plants, and oil testing commercial laboratories, it is suitable for elemental analysis of various new or reused lubricating oils, hydraulic oils, light fuel oils (gasoline and diesel), heavy oils, lubricants, antifreeze, industrial domestic water, and turbine flushing water.

Application field:

Military field

Aerospace field

Electricity industry

Transportation industry

Performance indicators:

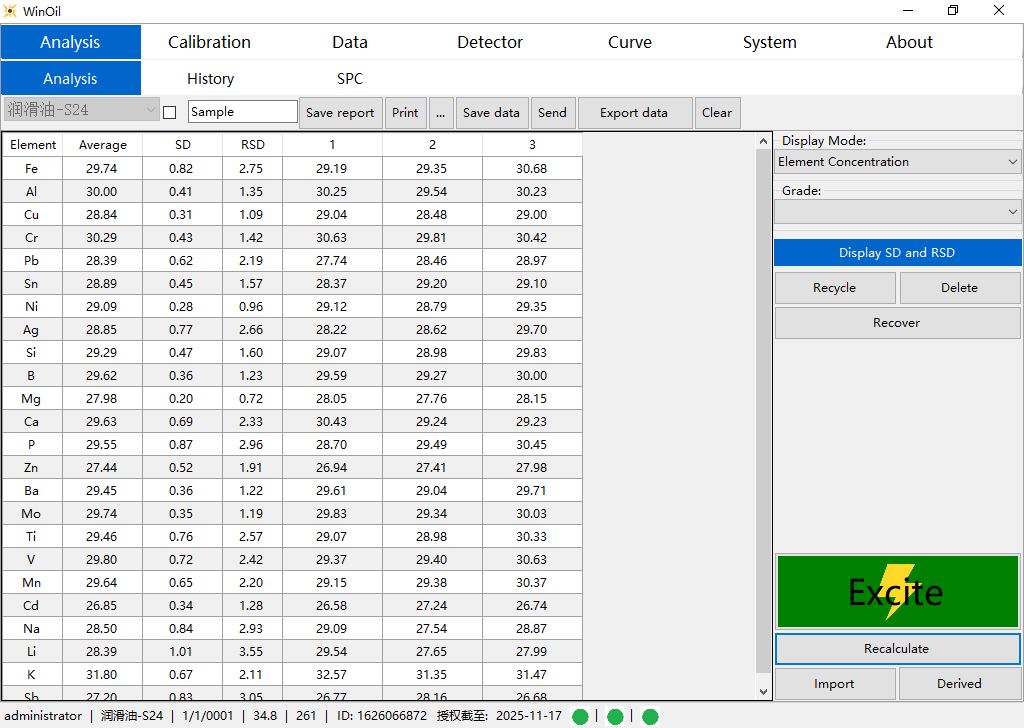

24 elements (Al, Ba, B, Ca, Cd, Cr, Cu, Pb, Mg, Mn, Mo, Ni, P, Si, Ag, Na, Sn, Ti, V, Zn, Fe, K, Li, Sb) can be analyzed synchronously, and the elemental composition of trace metal elements, pollutants and their additives in oil samples can be accurately determined;

Detection range: 0-1000ppm (19 elements, Al, B, Cd, Cr, Cu, Pb, Mn, Mo, Ni, Si, Ag, Na, Sn, Ti, V, Fe, K, Li, Sb), 0-6000ppm (5 elements, Ba, Ca, Mg, P, Zn);

Adopting high-performance CCD optical system;

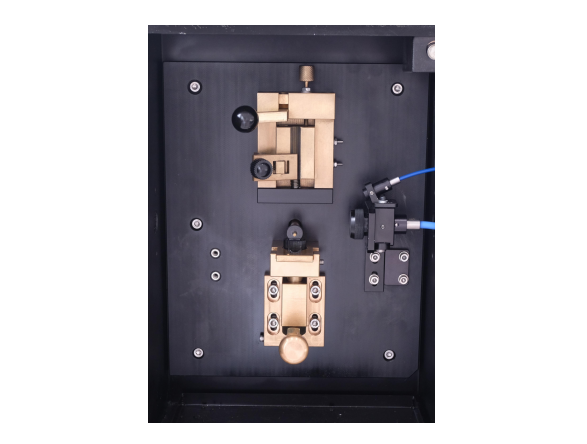

Dual optical system, Roland circle optics and C-T optical path;

Dual fiber optic input optical signal;

No gas or other chemical reagents are required to assist in excitation, and the oil sample does not require pre-treatment. It can be directly placed in a sample cup for testing;

*Optical focal length: 500mm;

Spectral range: 200-800nm;

Optical system constant temperature control: 38 ° C ± 0.1 ° C, effectively ensuring accuracy and stability;

The sample testing speed is fast, and the single testing time is not more than 30 seconds;

High detection accuracy, detection limit less than 1ppm;

Sampling volume: about 2mL;

*Built in graphite electrode grinding machine;

*Built in printer;

*The device is equipped with an integrated built-in industrial control computer, which is convenient for special use at any time;

The equipment has an exhaust structure to prevent cross contamination;

*Dimensions: 660mm * 360mm * 520mm (length * width * height);

*Weight: approximately 64kg;

*Equipped with a self-developed spectral analysis expert system, it has data management, trend analysis, and prediction functions, which can be used to analyze and judge the current working conditions of equipment/equipment, and make predictions for future working conditions, thereby providing effective basis for the correct use and maintenance of equipment.

Performance characteristics:

Patent digital arc light source, solid-state source excitation, ensuring constant current source frequency output, without the need for periodic cleaning or cleaning of excitation source errors;

Adopting a high-resolution solid-state CCD sensor optical system, with a single pixel of 3648 bits and a pixel size of 8 * 200um, higher pixels can detect more effective spectral intensities;

Spectral analysis application software based on Windows system, which can run on Windows 7, Windows 10 and other systems, integrating instrument control, data management, qualitative and quantitative analysis functions;

Single desktop instrument, computer system and motor grinder are built into the instrument, with a small overall volume and easy transportation;

Short heating time, high reliability, suitable for naval environments;

Without the use of argon, oxygen, or other chemical solvents, the oil sample does not require pre-treatment and can be directly placed in a sample cup for testing;

Built in printer and electrode grinder, easy to operate.